Waste co-processing in cement production is a sustainable solution!

Waste co-processing in cement kilns is now recognized as one of the most sustainable solutions for the treatment of non-recyclable waste.

According to scientists, the world generates approximately 52.3 billion tons of waste per year, with at least 32.5 percent of this total not being safely treated. Without measures to reduce waste-disposal, the total amount of waste generated globally is expected to increase by 70-75 percent by 2050 compared to today.

Normal industrial solid waste is produced in far greater quantities than domestic solid waste. The amount of normal industrial solid waste increases significantly as income levels increase. Normal industrial solid waste generation in high-income countries can reach 43.25 kg/person/day, while the global average is 14.52 kg/person/day.

Photo: Waste is pre-processed for co-processing

The collection of waste is a critical first step in waste management. Waste collection rates in high-income countries reach 98-99 percent. In low-income countries, only 42-45 percent of waste is collected in cities, with the remaining 21-24 percent collected outside of cities.

In Vietnam, according to the World Bank's Assessment Report on the Management of Domestic Solid Waste and Hazardous Industrial Solid Waste, the amount of waste in Vietnam is increasing, with the volume generated more than doubling in less than 15 years. Vietnam's waste management is labor-intensive and inefficient, and fees are insufficient to cover operating costs for collection and treatment.

According to the report of the Ministry of Natural Resources and Environment, the amount of daily-life solid waste generated in urban areas is approximately 38,000 tons/day, and in rural areas is approximately 32,000 tons/day; industrial solid waste is approximately 69,000 tons/day; and normal medical solid waste generated in hospitals and medical facilities is approximately 403 tons/day.

Using waste as an alternative fuel in industrial production is regarded as a critical and long-term solution. The method of waste co-processing in the cement industry is a solution with many advantages, due to the use of high-temperature incinerators in the production line, which allow the burning of most different waste, high rate of heat recovery, and no stringent requirements for waste component classification, leaving no ash or slag, safe for the environment...

The 2011 Basel Convention defines co-processing as "the use of waste in the production process for the purpose of energy recovery and/or material recovery, resulting in a reduction in conventional fuels and/or raw materials through replacement".

This is also a term used in industrial ecology to describe industry's role in reducing environmental burdens through product life cycle development.

The Basel Conference further defines, co-processing as a process "that can aid in resource recovery, recycling, recovery, direct reuse, or replacement".

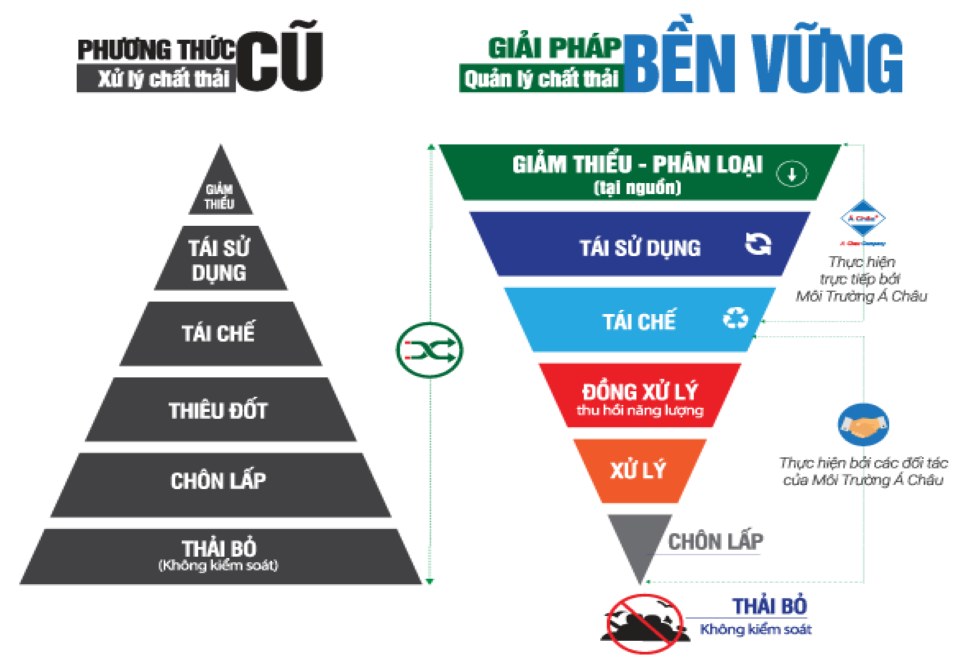

On the waste management tower, co-processing is ranked higher than landfill or incineration, physico-chemical methods, only after reducing, reusing and recycling.

Photo: Sustainable Waste Management Tower

View more

Binh Phuoc Cement used waste as fuel to save money on production!

What else should we know about co-processing?

Source: Ximang.vn