Waste as an alternative material in cement production!

Still, many people believe that coal costs are growing and that the Cement industry is "hot" in terms of finding solutions to home and industrial waste as alternative ingredients in cement manufacture. Indeed, the cement industry has long sought alternate raw materials with the combined goal of "protecting the environment while delivering economic efficiency."

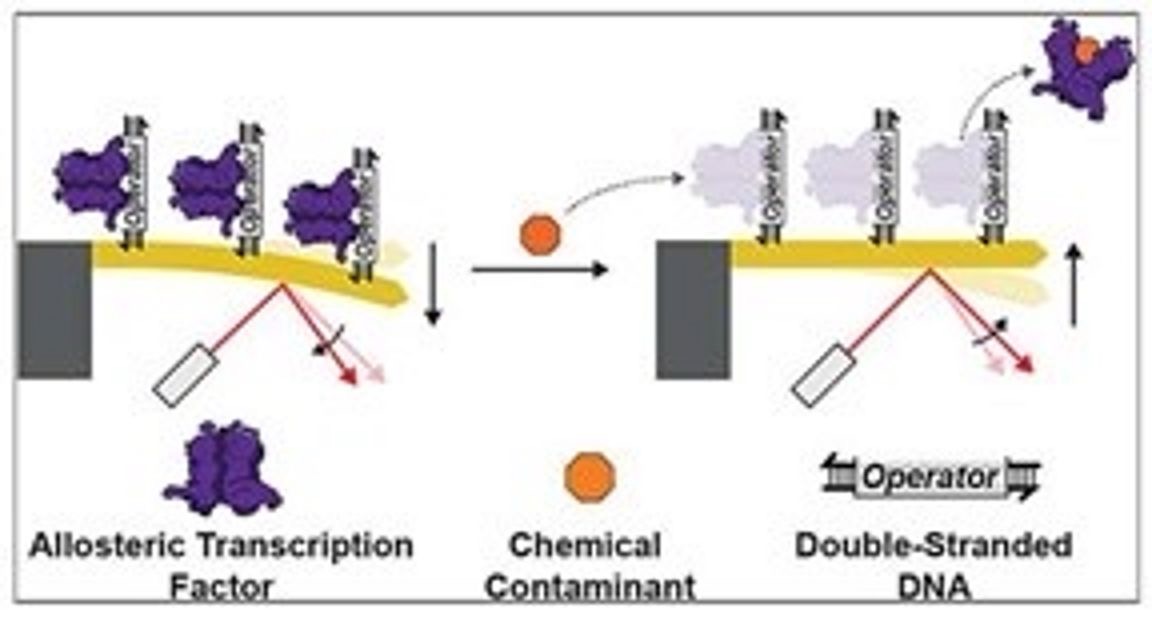

The waste incineration system at the kiln factory.

The cement industry must meet three requirements while implementing a "Co-processing" solution. First, supply must be stable long-term. Secondly, the choice and investment of appropriate technology for each type of waste, waste if there are distinctive characteristics and different components, At least staying in a circular economy.

The area offers waste: a large amount of junk that is distributed, concentrated, and almost entirely unclassified. This is one of the distinctions between the use of garbage and waste as alternative energy in Vietnam and many other places across the world. Waste is most likely collected in various plants. Furthermore, with split or reversal technology, that difference develops in manufacturing because supply is reliable and there are too many various types, forcing users to discover and use diverse technologies. To begin with, there is processing, separating, blending, and processing.

There are two types of waste used: high-thermal waste, such as textiles, leather, and skins, which are processed using pure technology, and livelihood waste, which is collected and mixed into storage before combustion. The first group homogeneously processes the waste, while the second group classifies the waste at factories or out-of-factory facilities and redistributes it to manufacturers who generate higher-value energy. This leads to the production of recycled products like plastics and nitrates, which are more economically valuable than coal replacement.

Waste incineration technology in cement clinker furnaces varies greatly, with some companies importing combustion technology from abroad and others developing it based on research and international experience. Complex issues like life waste treatment and volatile substances like alkaline sulfur arise, posing challenges in finding alternative fuels for coal and reducing dependence on the source.

Economic efficiency is significantly impacted by factors such as garbage, cement business waste, suppliers not paying, and subsidies for shipping. The moisture content and impurities in garbage waste also impact transport routes, warehouses, and assemblies.

The cement industry, clinker, and cement industries are exploring waste as coal replacement fuels. However, the effectiveness of this approach depends on factors like careful research, accuracy, and wisdom in technology selection, which are crucial for a business's success in this direction.

Source: Ximang.vn