Vicem Ha Tien in Vietnam saves expenses by using waste as fuel in production!

Vicem Ha Tien Cement Company is a market leader in cement production and is a pioneer in promoting the circular economy towards green. Harness waste as an alternative fuel (coal, oil) in cement production is being applied at the Binh Phuoc factory and has been very effective for the enterprise.

Vietnam has about 60,000 tons of domestic waste thrown into the environment per day. By 2025, the rate of domestic waste generation is projected to increase by 10% to 16%/ year. For years, waste has been handled by burial, but it is actually an essential resource in the circular economy, especially for the cement industry.

In 2015, Vicem Ha Tien analyzed the calculation and installation of a cashew shell burning system that replaced part of the charcoal at the Binh Phuoc cement factory to replace about 20% of the total heat consumption, reducing the price of clinker production. However, the current supply of cashew shells is scarce, and there needs to be a more stable supply for the operation of the kiln.

Photo: Binh Phuoc Cement Factory of Ha Tien 1 Corporation.

The reality is that Vicem Ha Tien Cement Company has implemented measures to find alternative fuels, such as surveying, researching, and planning to use familiar industrial waste sources such as rag shoe soles..., which have calorific value and quality characteristics suitable for burning in kilns to partially replace coal dust and diversify alternative fuel sources besides cashew shell residue, which is currently used and exploited. And maximize the proportion of alternative fuels.

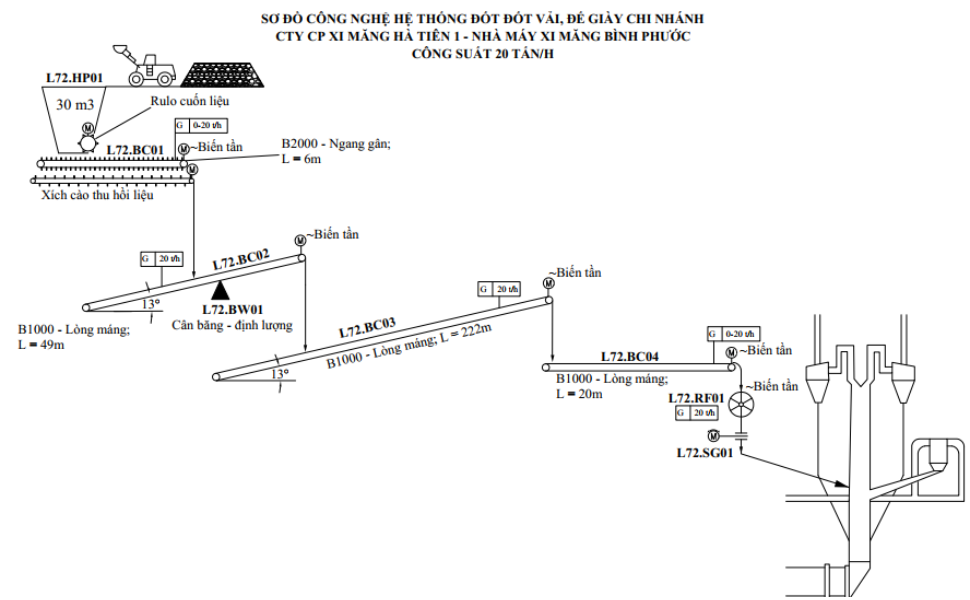

The fabric materials routine, the shoe sole, is supplied by the next truck loader, L72.HP01, with a volume of 30 m³, in the arrangement of a data roller with a motor frequency, can be upgraded to handle height screen data. Tensile conveyor belt L72.BC01, with a capacity of 20 tons/hour, is a conveyor belt with motor frequency. On the outside, there is a cleaning drum roller to prevent sticking to the conveyor belt. System for transporting base fabric and shoe soles to the 4th floor of the pre-burning tower. New construction of conveyor belt L72.BC02 with a capacity of 20 t/h with a motor that receives the next frequency from the conveyor belt L72.BC01. This L72.BC02 conveyor from the tunnel in the residue warehouse controls the expansion of data transfer to the L72.TS01 redirection station to transfer data to the L72.BC03 conveyor belt.

On conveyor belt L72.BC02, there is a belt weighing and measuring system L72.BW01 was installed to feedback and control the material unloading conveyor belt L72.BC01. Material conveyor L72.BC3 has a capacity of 20t/h with an inverter motor at the transfer station L72.TS01 to receive material from conveyor belt L72.BC02 to transfer material to the 4th floor of the heat exchanger tower. The active end of conveyor L72.BC03 is placed on the cantilever beam system installed on the 4th floor and dumps material onto conveyor belt L72.BC04.

The system transports shoe sole rags from the 4th floor of the heat exchanger tower to the calciner lower combustion chamber. Conveyor L72.BC04, with a capacity of 20 tons/hour, has an inverter motor that receives material from the belt conveyor L72.BC03 and moves it to the rotating feeding valve position L72.RF01. Could you install a new rotary feeding valve L72? RF01 combined with safety sliding door opening and closing valve L72.SG01 to supply rags and shoe soles to the burning position under the calciner.

The scrap-burning wire shoe rack works independently and can burn in parallel with the existing shell-burning system.

The fabric scrap diagram shows that shoe soles are fed into a 30 m³ receiving hopper with an anti-clogging roller and inverter motor. The ribbon conveyor L72.BC01, with a 20t/h capacity, is used to transport rags and shoe soles to the pre-baking tower's 4th floor. A new conveyor belt L72.BC02, with a 20t/h capacity, is installed to receive material from the material retractor conveyor L72.BC01. The material is transported to the L72.TS01 diversion station and dumped onto the L72.BC03 conveyor belt.

The burning point is selected where the burning is located above the neck of the oven to follow the pipe to the cyclone on the first floor. The length of the pipe that the fabric is crumbling, the lightweight shoe stand can burn out during drying, with the hot wind flying over the cyclone without falling to the top of the kiln.

A report by Vicem Ha Tien, using the "Co-Processing" approach would result in savings of 15 billion VND by 2021. Since the advent of traditional industrial waste treatment systems, it has resulted in significant social and environmental advantages. Traditionally, industrial waste (crumbs, shoes) was buried rather than squandering a huge amount of the expense of treating it, but this has a direct impact on the environment.

Rely on the system has developed a market supply chain by collecting, transporting, processing, and utilizing the heat from the burning of industrial waste. Grateful resulted in significant accomplishments such as lowering processing costs through traditional burial, establishing new market supply chains, saving money on coal burning, and lowering CO2 emissions to the environment while burning fossil fuels.

Source: Ximang.vn