Modular wastewater treatment system

Introduction

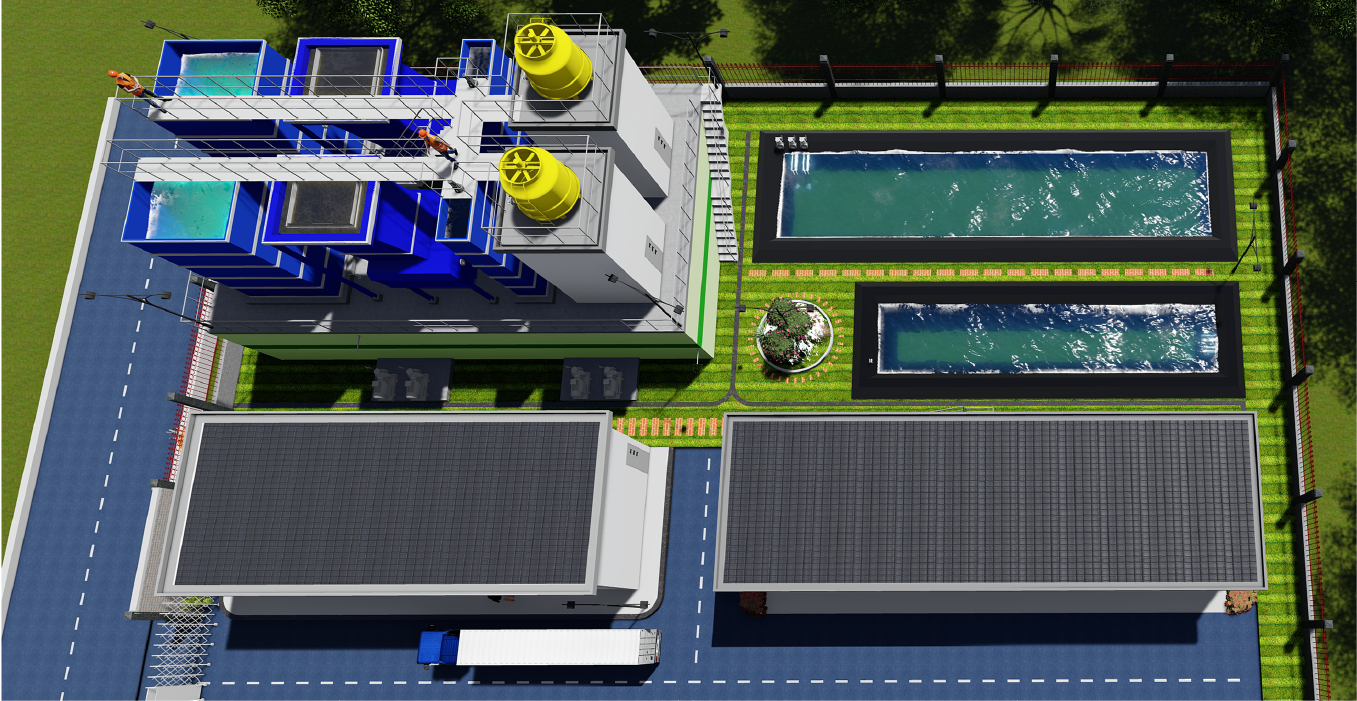

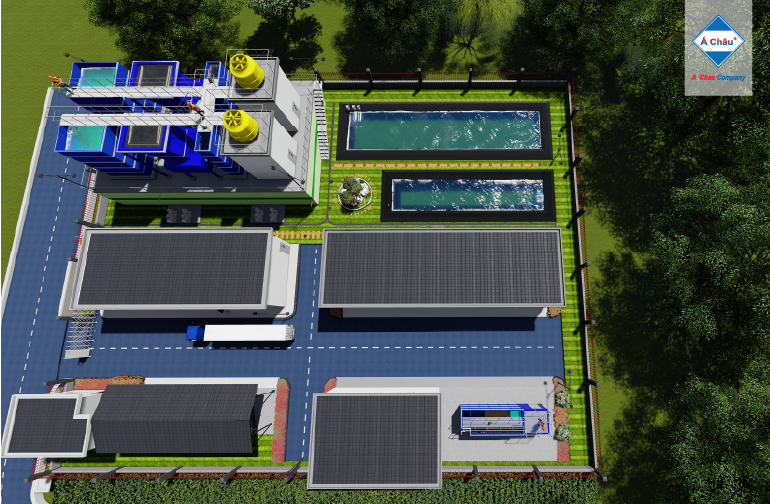

What is the modular wastewater treatment system?

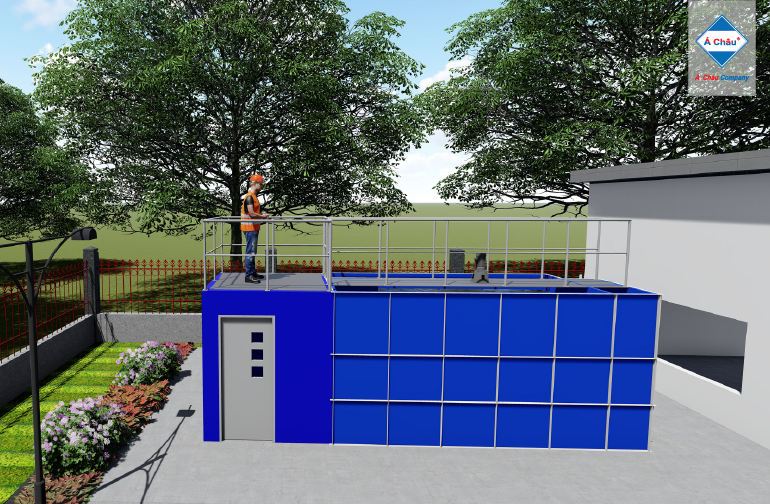

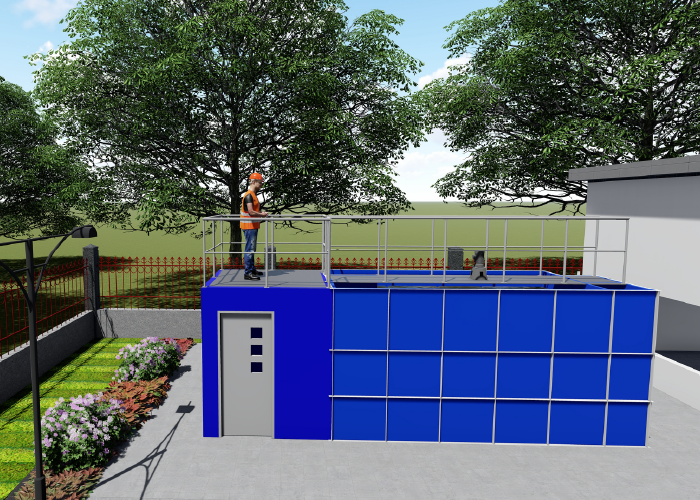

The modular wastewater treatment system (module), hereinafter referred to as Module-ACE, is a product specializing in domestic wastewater treatment designed by A Chau Environment's engineering team to be lean, easy to operate - maintain, save space, optimize investment costs, can be moved,... and especially an effective tool to treat domestic wastewater with the flow rate less than 30 m3/day and night.

Which objects does the modular wastewater treatment system (Module-ACE) serve?

A product of A Chau Environment - optimizing the environmental value chain to Customers

MODULE - ACE was first introduced in 2015. In the process of product operation and implementation, there are still some shortcomings, our technical team continue to upgrade and optimize. By 2020, the latest version has been introduced, bringing useful and practical values to customers.

Wastewater treatment technology

It is the location where wastewater is generated from two toilet areas during the company's activities are collected, then pumped and transferred to the equalization tank.

Helping in the regulation of discharge flow due to uneven discharge at various times of the day. To avoid shock loads for the biological treatment stage, the conditioning tank is required to regulate the flow and pollution load. A system of two rotating air blower combinations aerates the wastewater in the conditioning tank. sessions designed to increase turbulence, prevent sedimentation, and avoid odor-causing anaerobic decomposition.

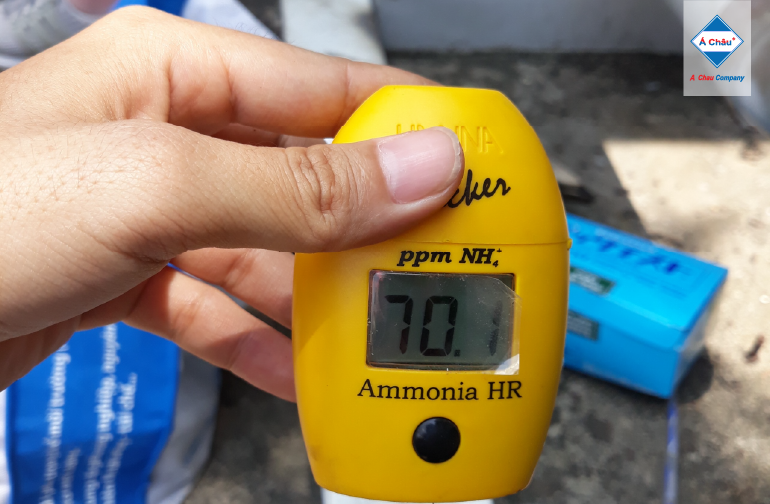

In the anoxic tank, products from the activity of anaerobic microorganisms are used to treat the amount of nitrogen present in the wastewater.

The MBBR (Moving Bed Biofilm Reactor) wastewater treatment technology uses microbiological techniques to adhere to the layer of material using a buffer material carrying microorganisms, resulting in a high density of microorganisms in the treatment tank. making pollution parameter treatment more effective.

The residual sludge from the Aerotank tank will separate from the microbial film and carry the wastewater to the settling tank, assisting in the separation of clean water from sludge. Microorganisms will form large flocs and fall to the tank's bottom by gravity. The sludge at the tank's bottom is partially pumped and circulated to the Anoxic tank.

Wastewater flows to the intermediate tank following phase separation in the sedimentation tank. After phase separation in the sedimentation tank, a filter pump and pressure filter column are placed in the intermediate tank to remove remaining residue. The filter column will be washed after each filter cycle, and the filtered water will be recirculated back to the equalization tank.

Task:The amount of bacteria in the wastewater has been reduced by about 90 ÷ 95% after the biological treatment process, but the wastewater still contains many pathogenic microorganisms. As a result, to remove the majority of the remaining bacteria, wastewater must pass through a chlorine disinfection tank.

Advantages

Module materials: (Inox, FRP-coated CT3 steel with anti-rust epoxy paint, composite);

Less equipment was used, prioritizing the lifting air technology;

Package integration of block items, no additional costs for grease separation;

Power cost is reduced by ½ when compared with conventional technology;

Low operating costs;

Upgrading the system easily by adding modules or substrates to increase processing capacity by 20-30%;

Easy maintenance;

Moving and installng to another location easily

Disadvantages:

Restoration of the system every 3-5 years: When using CT3 steel, recoat the FRP. Assess the air line, the valve system, and the overall equipment,...

Semi-automatic operation requires daily checks by the operator;

Floating on the ground

Not guaranteed with production wastewater

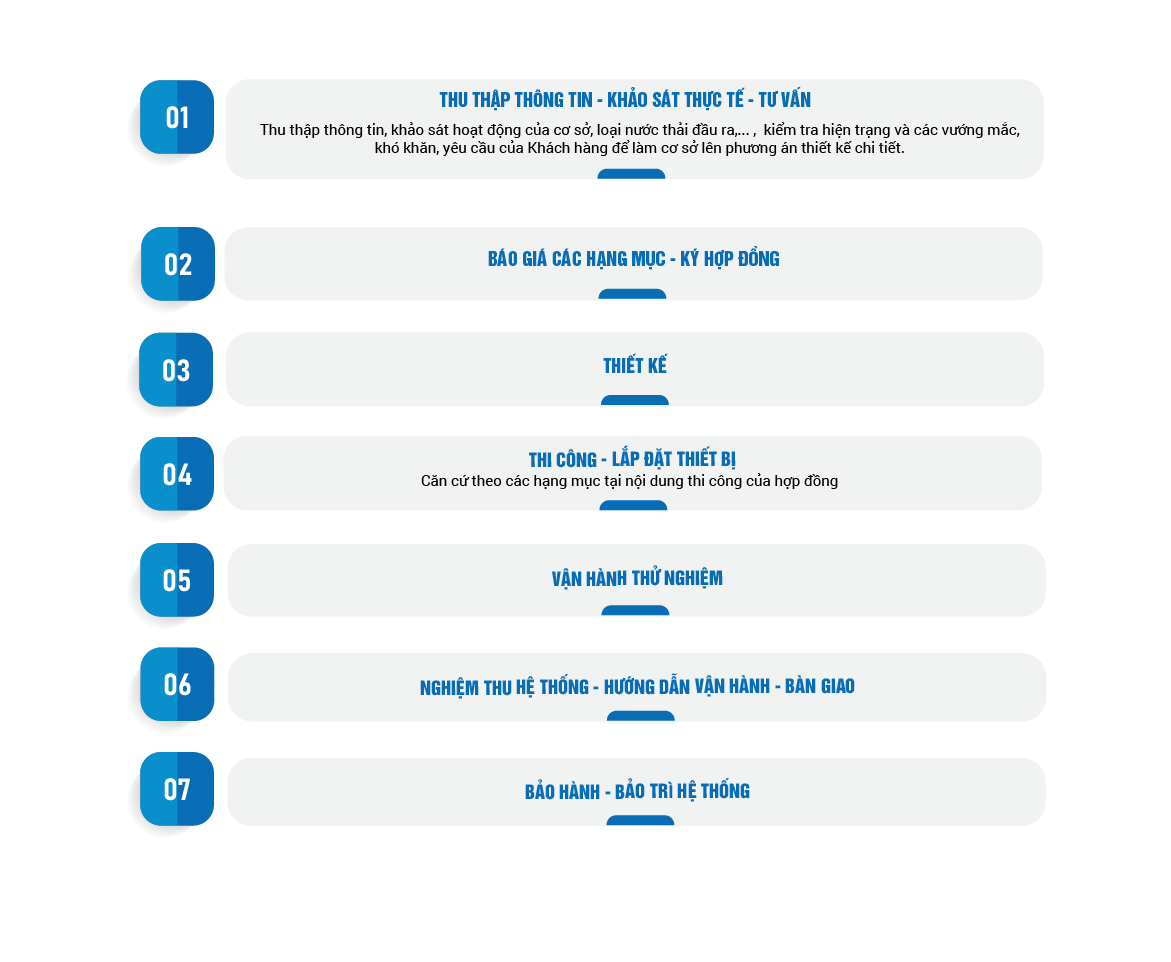

The provision process of services

Quotation

Please contact us for a detailed consultation and quotation for each project below!

Our regional Customer & Partner services center in Vietnam:

Northern Services Center: 033 8351122

Central Services Center: 0902 450585

HCMC – Eastern Services Center: 033 8351122

Southern Services Center: 0902 912586